Typically an Automotive passenger vehicle consist of 7,000+ parts. In which 20% of Components are depends on Electrical and Electronics and 80% Consist of Mechanical.

There are so many dimensions to work in the automotive field that electric cars cannot terminate the need of Mechanical engineers.

Let us consider a scenario where electric cars become well established. Now ask yourself these questions

- Who will design the Interiors / exteriors?

- Who will look after the raw materials needed?

- Who will do the research & development?

- Who will be responsible to add new features to the car?

- Who will look after the manufacturing?

And such many questions can be asked whose sole answer is a Mechanical engineer. Yes e-cars will terminate need for engineers in engine domain. But still in the power generation Mechanical engineers can still play a role.

The international federation global automotive mobility, has defined three levels of skill sets required for the automotive engineer of tomorrow, building Engineering Expertise is the ground level, broken down into mechanical, electrical, electronics and computer engineering. The next two levels are Integration Expertise and a Growth Mindset.

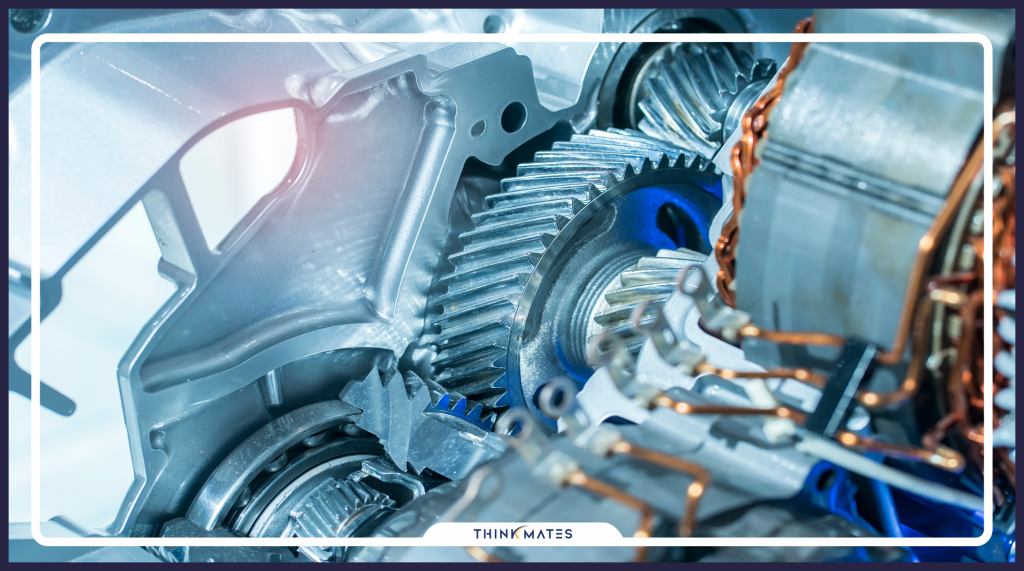

Among the basic Engineering Expertise, mechanical engineering is the very basic. It ensures that vehicles have a structure in place with necessary strength to withstand the forces it is subject to. At the same time, it cannot be too bulky and waste fuel for moving around. The design of the structure of a vehicle is an exercise of optimization based on ‘mechanics of solids’, the properties and geometry of the material used. The outer body of the vehicle should take into account aerodynamic properties, as it will move at high speed and face heavy head wind. The ‘drive’ part also belongs to mechanical engineering, from the battery which supplies power to the drive train which modulates the torque depending on different situations – a stationary vehicle moving vs a vehicle already moving at high speed.

The drive train should deliver the optimum amount of torque for the vehicle based on each situation – acceleration, deceleration, starting from a stationary position, an upward or downward gradient etc., The optimum torque will ensure efficiency of the vehicle, drawing only the least amount of power required for each situation to conserve the battery charge.

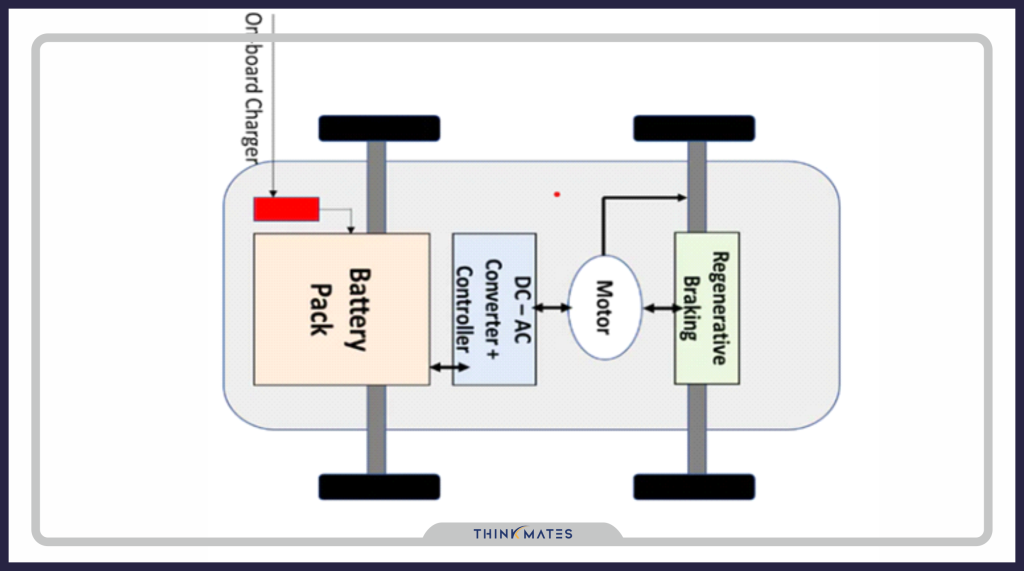

The most basic components of EV:

- The Battery Pack, comprising of multiple lithium-ion cells, stores the energy required for running the vehicle in the form of chemical energy. A car like Tesla Model S would require 6000 – 7000 AA batteries. The battery pack is the most expensive component, accounting for 40 – 50% of the price of EV.

- DC – AC Converter – The DC output of the battery is converted to AC that powers the motor.

- Electric Motor converts the electrical energy into mechanical energy and delivers it to the wheels via a simple drive train.

- On-board Charger converts the AC from the mains to DC and controls the current flowing into the battery pack.

- Regenerative braking is a way of taking the wasted energy from the process of slowing down a car and using it to recharge the car’s batteries.

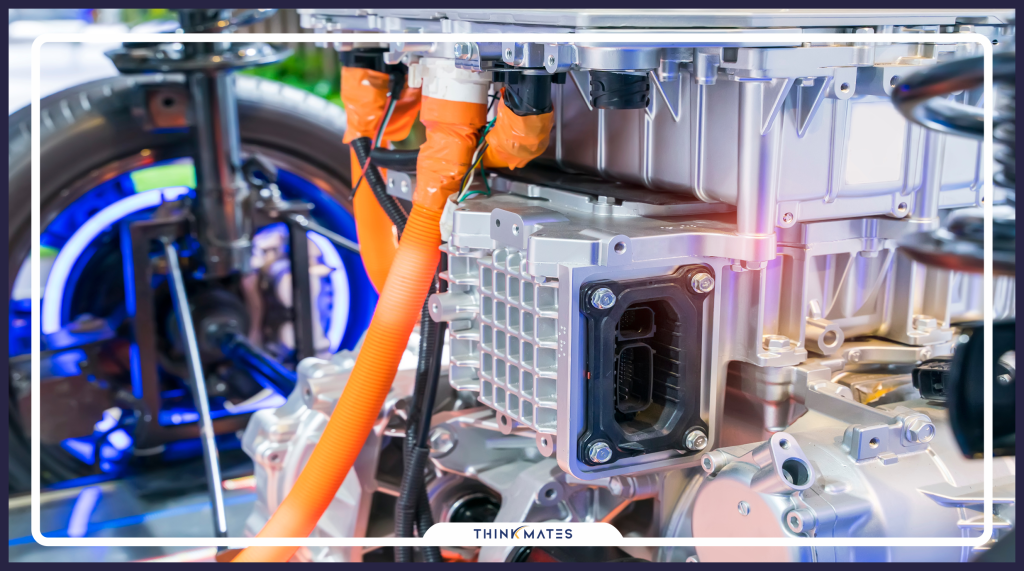

Other Components in Automotive Vehicle such as BODY DESIGN(BIW), TRIMS, INTERIORS, SEATING SYSTEM, Product development, POWER ELECTRONICS COOLING CHANNEL DESIGNING, DESIGNING COOLING SYSTEMS FOR ELECTRONICS (SUCH AS OBC,BMS), Battery packs design , Thermal interface materials selection , these are some newly added roles due to EV platform . The integration of the whole new powertrain (Electric motor drive) with the transmission, steering and suspension systems, Axles are in the hands of the mechanical engineers. See, I only say about Design sector Jobs. Similarly, there are many sectors in EV segment that needs help of mechanical engineers.

Conclusion: The EV segment expands the job market of Mechanical Engineers.