So, what manufacturing automation solutions are out there, waiting to be utilized by manufacturers, small and large?

Procurement

From supplier portals to Vendor Management Systems (VMS), the purpose of procurement automation is to free employees from time-consuming, repetitive tasks, so they can instead focus on the more important requirements of the business.

Order Processing

Sales and manufacturing orders can quickly become difficult to fulfill when business picks up, especially if you’re a bespoke manufacturer.

By automating this manufacturing process, you’ll be able to monitor orders in real-time, track customized orders, handle pricing calculations, store customer information, and adapt to any order changes.

Supply Chain

Automating your supply chain is going to help you with decreasing the delivery times of your products to customers. Also, you’ll be able to improve your routing manufacturing, which is especially important if you have products stored at multiple locations.

Customer Service

From upselling/cross-selling to automatic responses to queries during out of office hours, anything that can improve the customer’s shopping experience is only going to help increase customer satisfaction rates.

Production

Using automation in manufacturing industry is extremely important for manufacturers. Using software will allow businesses to improve bottleneck management, store bill of materials, and even make use of AI-assisted decisions. And if you outsource your production (or part of it), contract manufacturing software can be of huge help when it comes to managing inventory and processes at your suppliers’ locations and at your own.

Operations

Manufacturing process automation of your operations will allow you to improve your workflow, reduce your manufacturing lead time, and ultimately boost your bottom line.

So, these are the manufacturing automation solutions manufacturers need to consider using. However, be sure to read on as we look into Smart Manufacturing Software, an all in one solution that can perform all of the above tasks and functions.

The benefits of Using Automation in Manufacturing

The sooner you implement a manufacturing process software into your business, you’ll experience:

- An increase in labor productivity;

- A reduction in labor costs;

- A way of mitigating the effects of a labor shortage;

- A reduction or elimination of errors from abandoning spreadsheets or other documentation;

- An improvement to product quality;

- A reduced manufacturing lead time; and— Increased savings by avoiding the high cost of not automating your production.

- Also Improves the safety;

If you’re a small-scale manufacturer, with sale orders here and there, it probably won’t be necessary to get set-up with process automation systems.

But, once your business starts to expand, and you’re handling more and more orders, it will quickly become a no brainer when deciding if it’s time to upgrade your processes.

Even more so for D2C manufacturers because the assistance of automation will be able to help them truck along, as they’ve decided to go solo and cut out the middleman.

Automated Manufacturing with Smart Manufacturing Software

Automation in manufacturing industry is made easy and possible with Smart Manufacturing Software, which has been built by manufacturers, for scaling manufacturers.

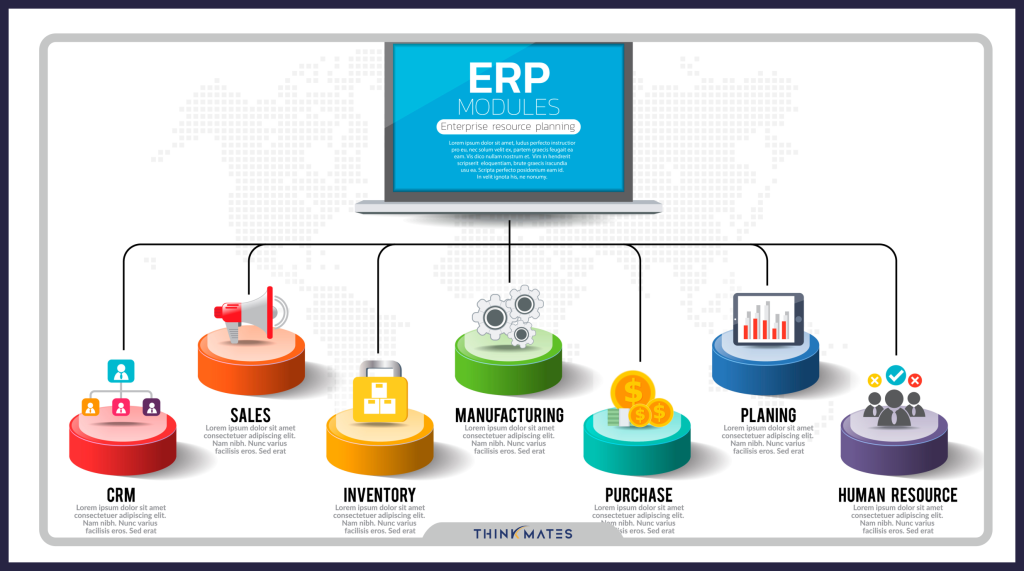

ERP is an all-in-one solution that, will not only streamline your business, but can integrate with your favorite platforms too, and help you with:

- Procurement;

- Order fulfillment;

- Your supply chain;

- Customer service;

- Production;

- Operations; and

- Process automation.

The other terms you’ll recognize from earlier in the article, but what is process automation?

The process automation definition is a term used to describe software which can automatically monitor and handle your inventory movement.

For example, ERP Solution can give you the full power of automated manufacturing with its unique auto-booking engine, designed to take available finished goods and raw materials, and allocate them to any sale, or manufacturing orders, you have open.

- But not only will you have access to this feature, but ERP also offers:

- On-demand access to your manufacturing costs;

- Synchronization with your accounting software like QuickBooks;

- Finished goods and raw material inventory management;

- Inventory tracking of items on consignment or across multiple warehouses;

- Outsource manufacturing management;

- Manufacturing scheduling software;

- Efficient material purchasing plans; and

- An easy to understand, visual dashboard, which can centralize your entire business.